今日の製造業者は、かつてなく複雑な部品を作成しているため、検査がより困難になっています。 Waygate Technologies の産業用非破壊試験ソリューションにより、製造業者はこれらの複雑なコンポーネントとアセンブリーを生産速度で検査および測定できるため、イノベーションを前進させ続けることができます。

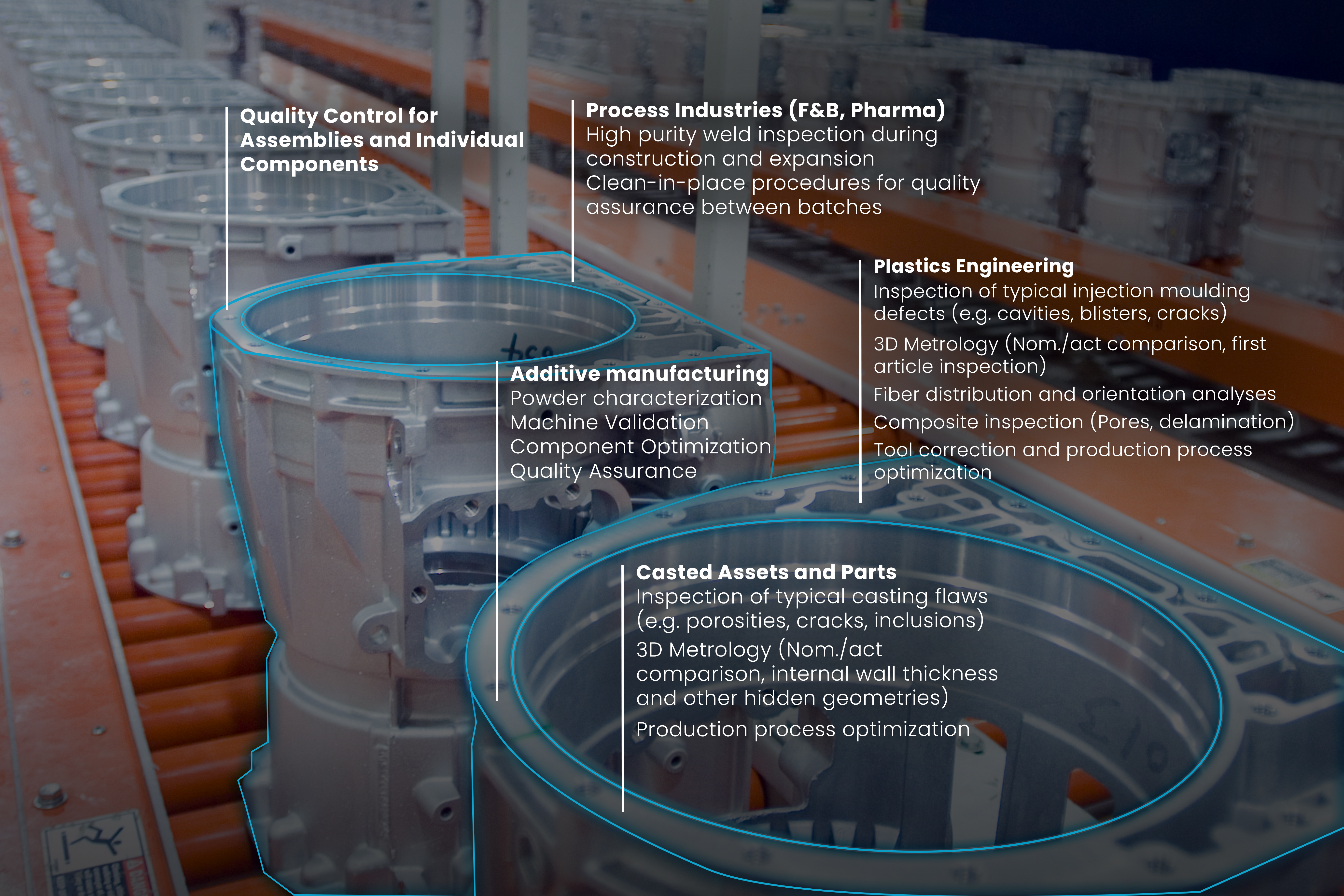

アディティブマニュファクチュアリング、鋳造アセットおよび部品、プラスチック工学から、プロセス産業や品質管理まで

業界の課題に対応する技術

Additive manufacturing enables the creation of more complex parts than ever before. Fortunately, there is one technique ready to inspect and measure complex internal structures that can’t be seen by any other non-destructive testing method: industrial CT.

Advanced CT enables design optimization, component validation and quality control for additive manufactured parts at the speed of production. Our CT systems combine the power of advanced healthcare components and unique high throughput technologies to create and analyze volumetric data sets of the as-built component with the speed and accuracy to support needs ranging from prototyping to production.

Quality control for safety critical metal bars, seamless pipes, and other products is provided accurately and efficiently with ultrasonic testing machines. World-class manufacturers of safety-critical industrial assets rely on our automated ultrasonic inspection systems to ensure the quality of their products.